Featuring a (2015) Full implanted N-type Bi-facial Si Solar Cell Line, Complete Cell Lab, Facility Support including; DI Water System, Waste Water Treatment, Scrubbers, Filter Press, Compressors (Over $60M in Acquisition Cost for the Tools)

Unprecedented Offering!! Immediately Available for Sale!!

Current State-of-the-Industry production lines presently rated at 200MW capacity, which are well suited for conversion to PERC+ Bi…

- Mission Solar Energy - SVD

Mission Solar Energy

Negotiated Sale (Buy Now)

State of the Art 200 MW Solar PV Cell Manufacturing Lines

Featuring a (2015) Full implanted N-type Bi-facial Si Solar Cell Line, Complete Cell Lab, Facility Support including; DI Water System, Waste Water Treatment, Scrubbers, Filter Press, Compressors (Over $60M in Acquisition Cost for the Tools)

Unprecedented Offering!! Immediately Available for Sale!!

Current State-of-the-Industry production lines presently rated at 200MW capacity, which are well suited for conversion to PERC+ Bi…

San Antonio, TX

Buy NowSale Details

Negotiated Sales

- Sale Preview:

Specs

| (2015) Full implanted N-type Bi-facial Si Solar Cell Line |

| 2015 ASYS Wafer Inspection Model SBL 01 DCS |

| 2015 Rena Batch Texturing Model BLO3 |

| 2015 Applied Materials SOLION XP Phosphorus Ion Implantation Systems S/N ES249057 & ES249058 |

| 2015 Applied Materials SOLION XP Boron Ion Implantation Systems S/N ES249057 & ES249058 |

| 2015 Rena Batch Clean |

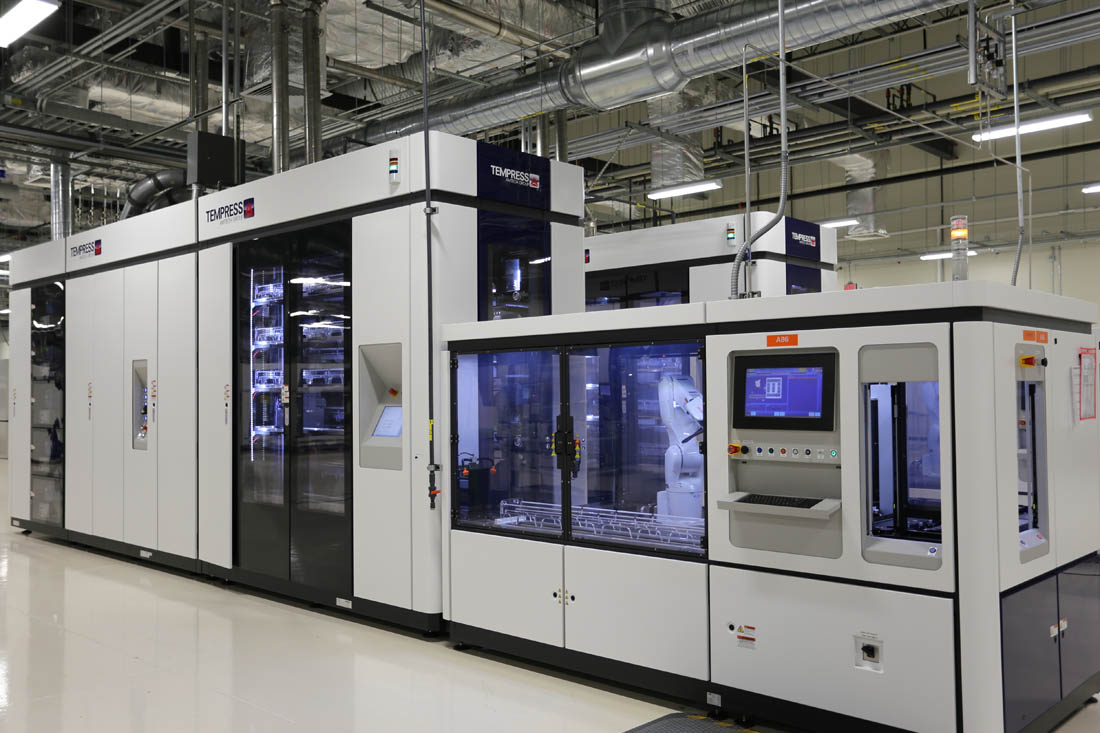

| (4) 2015 Tempress Annealing Tools Model TS1254 w/ QUANTUM Baumann Wafer Handling Systems Model TEMVAA-1000834 |

| 2015 Rena Batch Clean |

| 2015 ASYS Wafer Inspection Model SBL 01 DCS |

| 2015 Rena Batch Texturing Model BLO3 |

| 2015 Rena Batch Clean |

| 2015 Rena Batch Clean |

| (2) 2015 Tempress SPECTRA Batch Type PECVD Systems (Front Si02/SiNX) Model TS-81255 W/R2D Wafer Handling Systems Model 1QV0001 |

| (2) 2015 Tempress SPECTRA Batch Type PECVD Systems (Rear SiNx) W/R2D Wafer Handling Systems Model 1QV0001 |

| 2015 ASYS Modular Metallization Print & Sort Line (ULTRALINE Dual Lane Alingus) Model 550-01DCS |

| 2015 Despatch Dritech Furnace S/N 188665 |

| 2015 Despatch Safire Furnace S/N |

| 2015 ASYS Modular Metallization Print/Test Line Model SB01DCS, SPC03DCS, STH01D1CS, SPH01D2CS |

| 2015 ASYS Sorter Line Model SSD 01DCS |

| Research and Development Instruments |

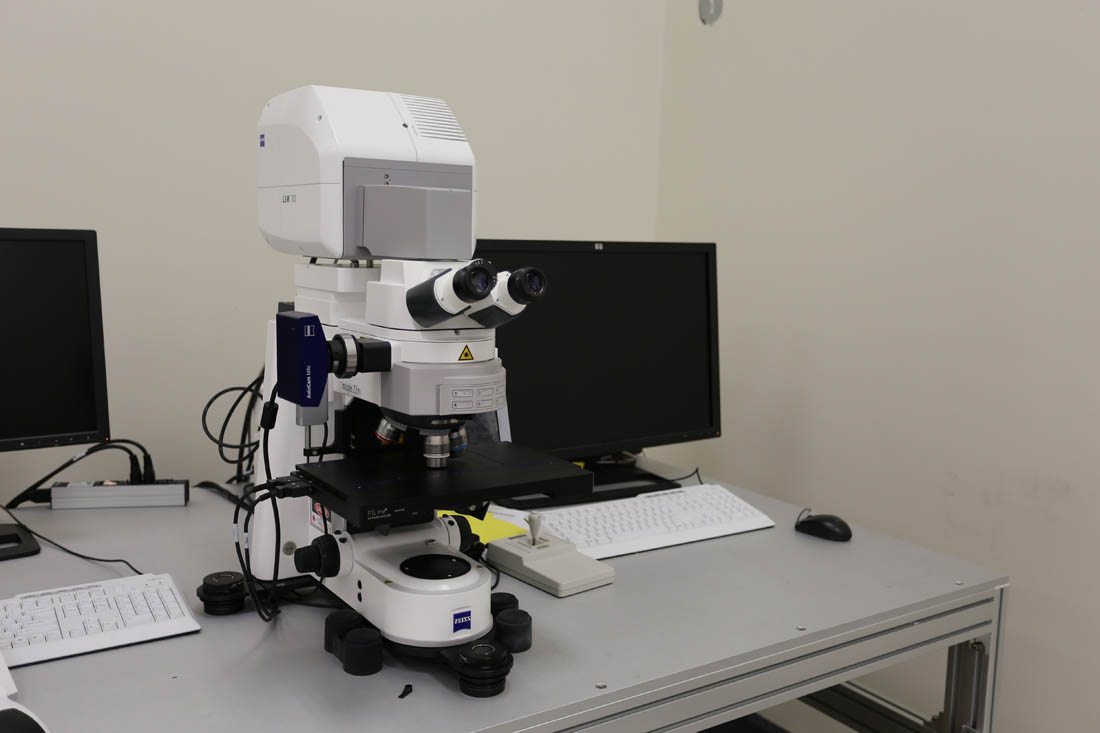

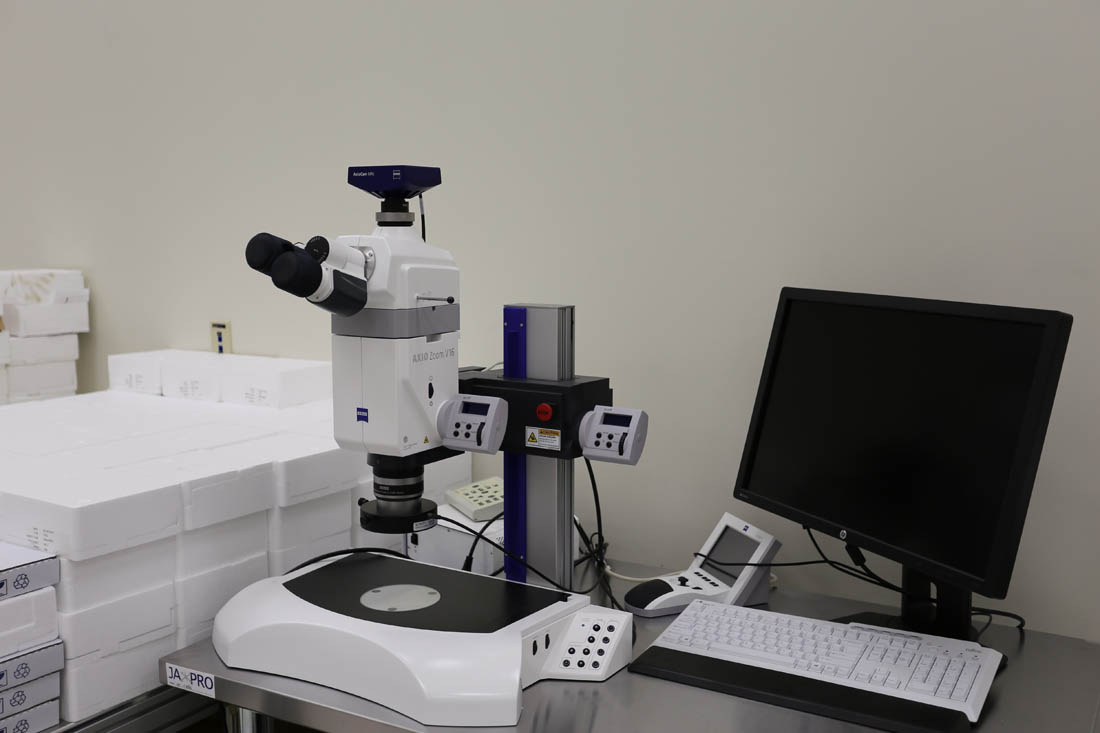

| Zeiss Axiom Zoom.V16 with Axiom Cam MRc |

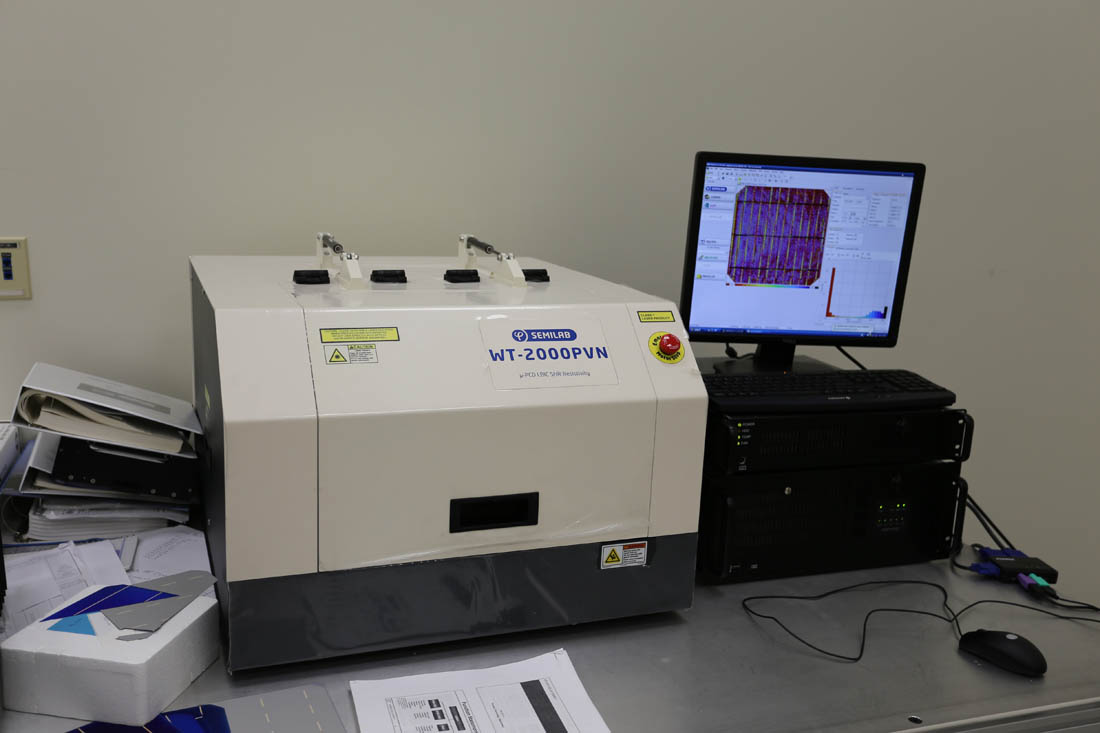

| Semilab WT-2000PVN Micro PCD |

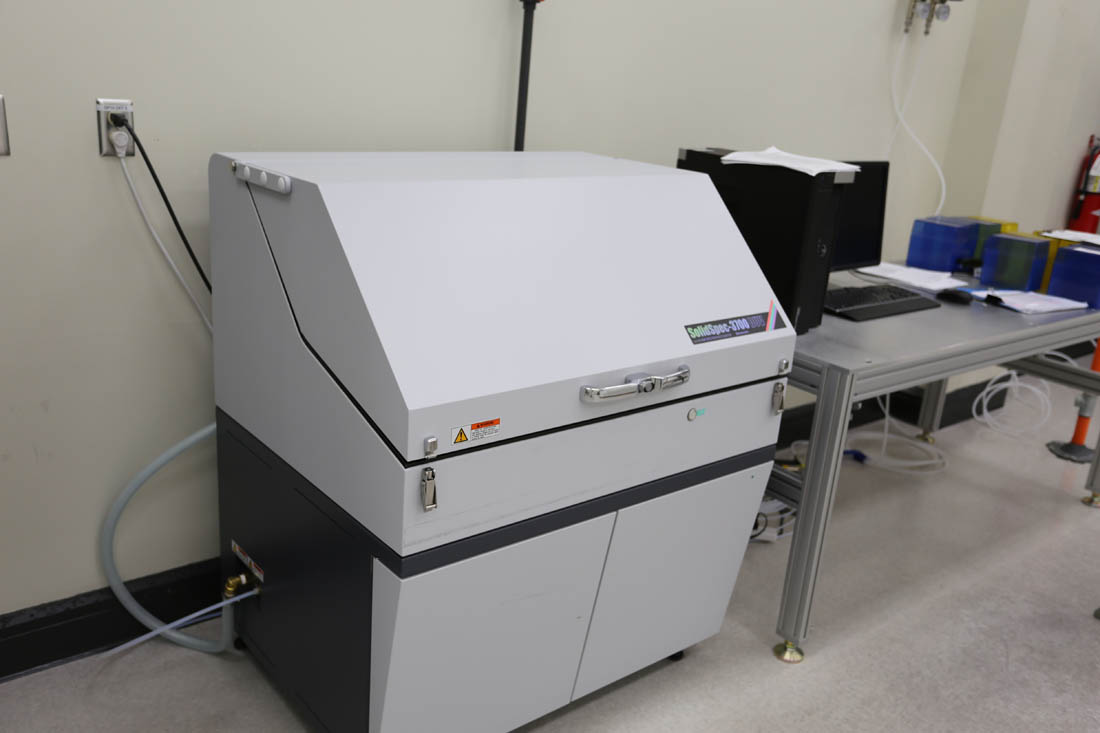

| Shimadzu SolidSpec-3700 DUV UV Spectrophotometer |

| Zeiss Axiom Zoom.V16 with Axiom Cam MRc |

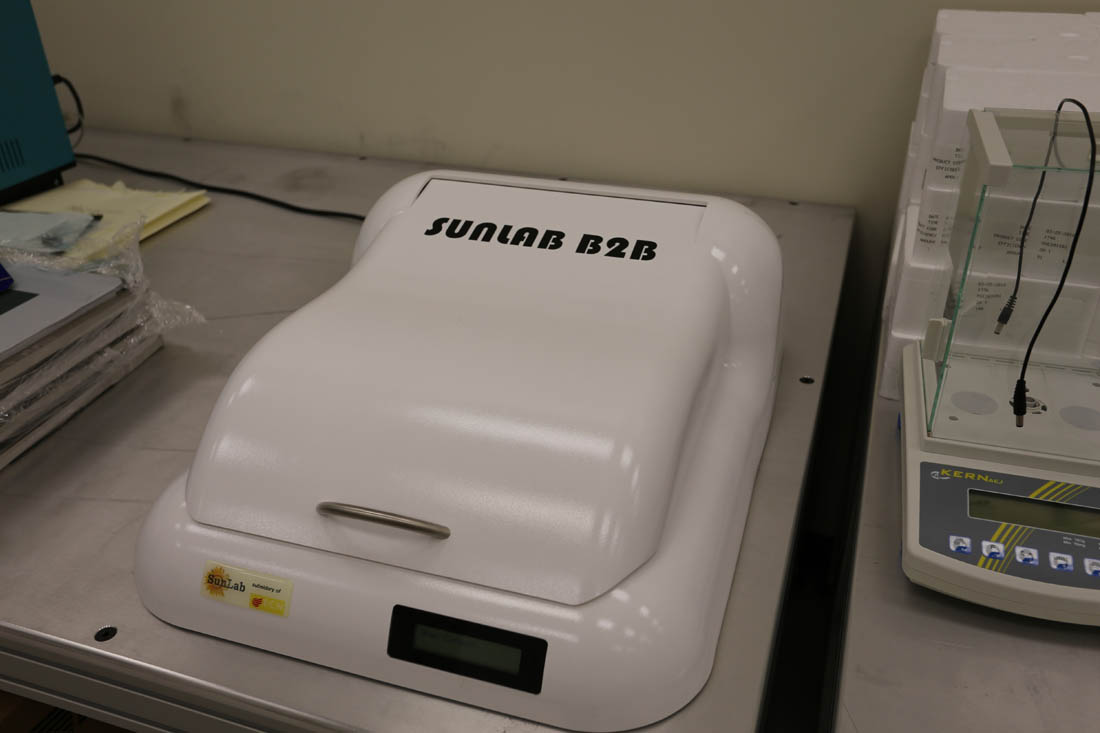

| KERN AEJ 100-4NM Scale |

| Sunlab B2B Measurement System |

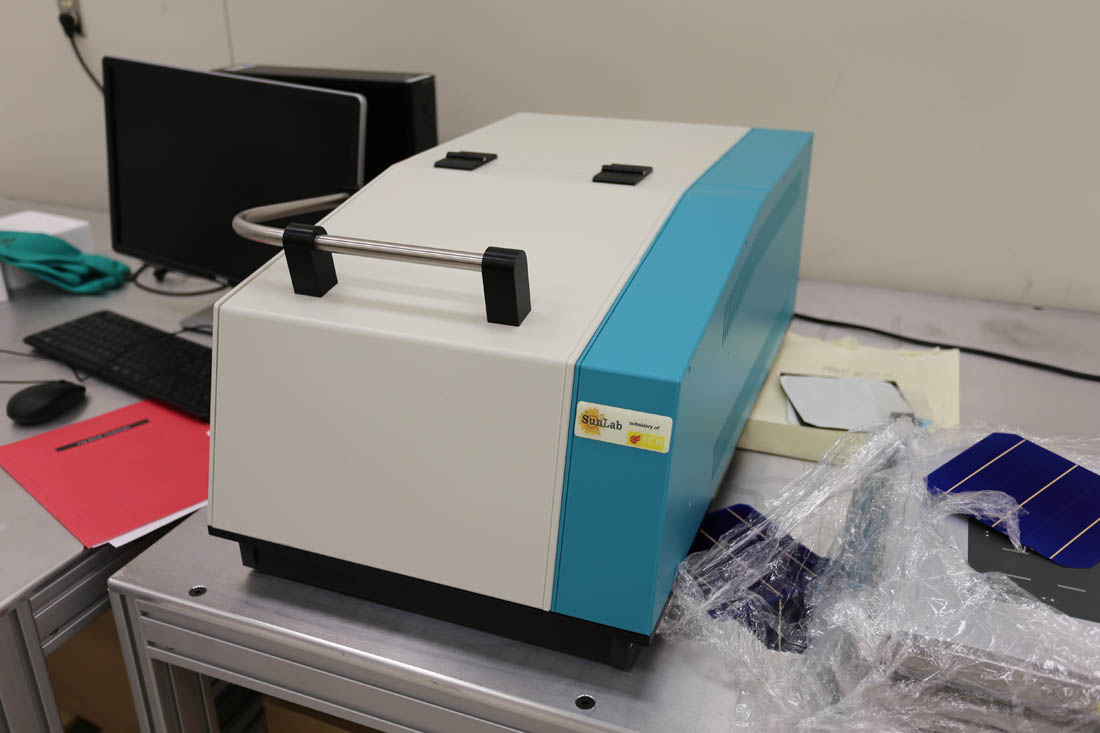

| Sunlab Correscan |

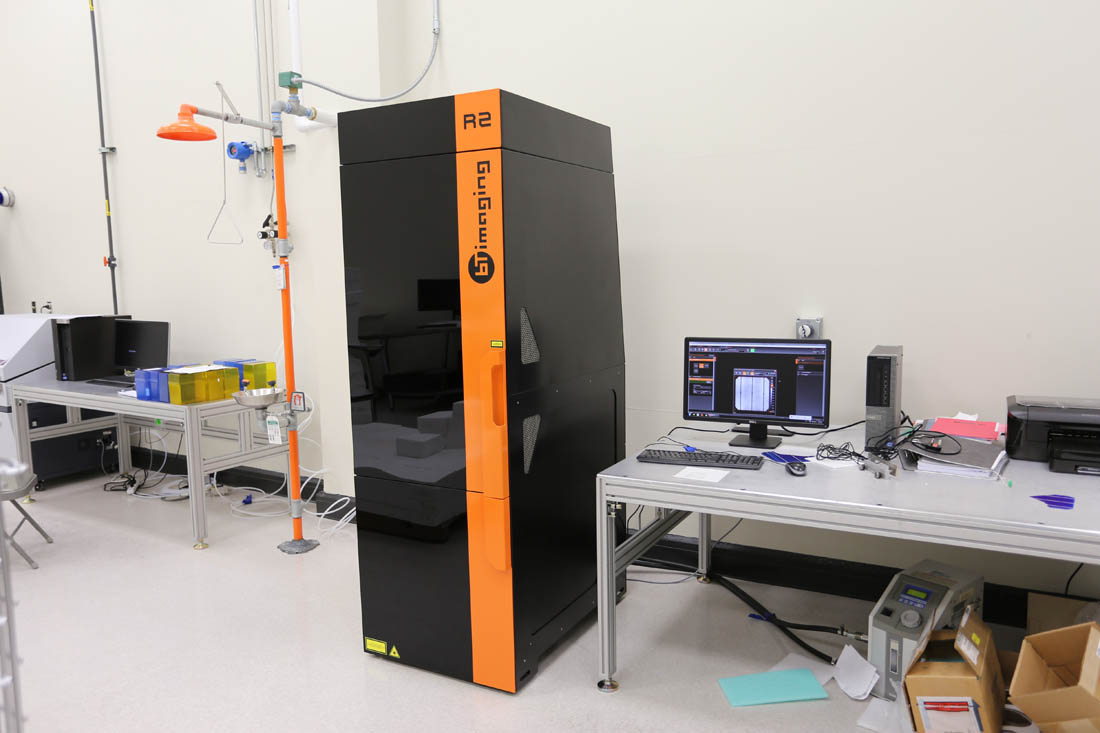

| BT Imaging R2 Measurement System |

| Grieve Oven Model 343 |

| SUNLAB Sheet resistance scanner SHER 10 9000 |

| Mactronix Carrier Changer LBST-600 |

| LABCONCO Chemical Fume Hood |

| LABCONCO Chemical Fume Hood |

| Materials Development Corporation Four Point Probe System with Advanced Instrument Technology CMT- Series |

| (2) Kern AEJ Scales |

| (1) SENTECH SE400adv-PV Ellipsometry |

Location(s) Info

Mission Solar Energy Overview

State of the Art Solar Manufacturing Equipment

All Tools were purchased in 2013 and then again in 2015

Mission Solar Energy is a manufacturer of solar PV modules. They offer a full line of high-efficiency N-Type and P-Type solar modules well suited for utility, commercial and residential applications. The Mission Solar modules are assembled in the USA from their 200 megawatt facility in San Antonio, TX.

View Facility Support ImagesMSE Cell Line Spare Parts Inventory

Event Notifications

Get notified about any updates to this sale.

For more information about this sale:

- John Carroll

- President

- (650) 678-3299

- [email protected]

- John Carroll

- n/a

- (650) 678-3299

- [email protected]

Additional Information

This sale is in conjuction with Onyx Asset Advisors

This sale is in conjuction with Onyx Asset Advisors

State of the Art 200 MW Solar PV Cell Manufacturing Lines

Featuring a (2015) Full implanted N-type Bi-facial Si Solar Cell Line (Can be used for P-Monocrystalline as well), Complete Cell Lab, Facility Support including; DI Water System, Waste Water Treatment, Scrubbers, Filter Press, Compressors (Over $60M in Acquisition Cost for the Tools)

Current State-of-the-Industry production lines presently rated at 200MW capacity, which are well suited for conversion to PERC+ Bifacial Cell Process, and Mission Solar achieved over 21% average cell efficiency in production. With conversion to PERC+, one could expect an increase in nameplate production capacity of 10% from these existing lines just through cell efficiency gains over the existing process flows.

Unprecedented Offering!! Immediately Available for Sale!!

- (2015) Full implanted N-type Bi-facial Si Solar Cell Line c/o:

- 2015 ASYS Wafer Inspection Model SBL 01 DCS

- 2015 Rena Batch Texturing Model BLO3

- 2015 Applied Materials SOLION XP Phosphorus Ion Implantation Systems S/N ES249057

- 2015 Applied Materials SOLION XP Boron Ion Implantation Systems S/N ES249058

- 2015 Rena Batch Clean

- (4) 2015 Tempress Annealing Tools Model TS1254 w/ QUANTUM Baumann Wafer Handling Systems Model TEMVAA-1000834

- 2015 Rena Batch Clean

- (2) 2015 Tempress SPECTRA Batch Type PECVD Systems (Front Si02/SiNX) Model TS-81255 W/R2D Wafer Handling Systems Model 1QV0001

- (2) 2015 Tempress SPECTRA Batch Type PECVD Systems (Rear SiNx) W/R2D Wafer Handling Systems Model 1QV0001

- 2015 ASYS Modular Metallization Print & Sort Line (ULTRALINE Dual Lane Alingus) Model 550-01DCS

- 2015 Despatch Dritech Furnace S/N 188665

- 2015 Despatch Safire Furnace S/N

- 2015 ASYS Modular Metallization Print/Test Line Model SB01DCS, SPC03DCS, STH01D1CS, SPH01D2CS

- 2015 ASYS Sorter Line Model SSD 01DCS

- Research & Development Instruments c/o:

- Zeiss Axiom Zoom.V16 with Axiom Cam MRc

- Semilab WT-2000PVN Micro PCD

- Shimadzu SolidSpec-3700 DUV UV Spectrophotometer

- Zeiss Axiom Zoom.V16 with Axiom Cam MRc

- KERN AEJ 100-4NM Scale

- Sunlab B2B Measurement System

- Sunlab Correscan

- BT Imaging R2 Measurement System

- Grieve Oven Model 343

- SUNLAB Sheet resistance scanner SHER 10 9000

- Mactronix Carrier Changer LBST-600

- LABCONCO Chemical Fume Hood

- LABCONCO Chemical Fume Hood

- Materials Development Corporation Four Point Probe System with Advanced Instrument Technology CMT- Series

- (2) Kern AEJ Scales

- (1) SENTECH SE400adv-PV Ellipsometry

- Facility Support c/o:

- Acid, Alkali, and NOX Scrubbers

The Acid, Alkali & NOX Scrubbers are a series of ducts and fans that exhaust the fumes and byproduct form the cell line equipment. Each scrubber is setup as a redundant system and has 2 separate units to be able to ensure a 100% run rate for the facility. The Acid Scrubber is capable of 57,420 ACFM and uses Sodium Hydroxide as it dosing agent. The Alkali Scrubber is capable of 20,580 ACFM and uses Sulfuric Acid as it dosing agent. The NOC Scrubber is capable of 1,300 ACFM and uses Sodium Hydrosulfate & Sodium Hydroxide as it dosing agent.- Chem Room Acid and Alkali Scrubbers

The Chemical Room Acid & Alkali Scrubbers are a series of ventilation ducts and fans that exhaust fumes from the chemical storage containers. The Acid system is designed as follows; 1,700 ACFM with an Overall Removal Efficiency of Nitric Acid Mist 99% > 20 micron, HF Acid 98% & HCI Gaseous 95%. The Alkali system is designed as follows; 700 ACFM with an Overall Removal Efficiency of KOH 99% > 20 micron, Ammonium Sulfate 99% > 20 micron & Ammonium Fluoride 99% > 20 micron.- Chemical Bulk Supply

- Chemical Room Exhaust Fan

The Chemical Room Exhaust Fan is a series of ventilation ducts and a fan used to achieve the required air change rate for the room. The system is designed for airflow up to 9,690 CFM and is a Class I.- Gas Cabinets – Ammonia, Nitrogen, Oxygen, and Silane

- Gas Room Exhaust Fan

The Gas Room Exhaust Fan is a series of ventilation ducts and a fan used to achieve the required air change rate for the room. The system is designed for airflow up to 550 CFM.- Gas Storage Room Systems

- RODI System Potable Water

Reverse Osmosis and Deionized Water (RODI) system is used to provide deionized ultra-pure water for plant production process. The systems starts with potable water, recycled water can be used depending on it existing concentration of pathogenic bacteria, parasites, and enteric viruses. This system has the recycled water components but do to existing recycled water conditions it was never implemented. The RODI system has the following capabilities, UF 273.4gpm, RO 112.7gpm, EDI 102.6gpm and the Polishing unit 110.1gpm. The water is sent through the following process; Auto Disk Filter to UF Unit to A/C Filter to Heat Exchanger, to UV Sterilization to Pre Micro Filter to 2nd Micro Filter to Membrane De-gasifier to EDI Unit to Heat Exchanger to TOC UV to Mixed Polisher Bed to Final UF Unit.- VOC Scrubber

The VOC Abetment Unit is used to convert volatile organic compounds and solvent-laden gas into carbon dioxide and water vapor. This is achieved by directing exhausted air into a porous bed filled with high temperature ceramic heat transfer media heated by Natural Gas. There are two units setup as a redundant system these two separate units ensure a 100% run rate for the facility. The system is capable of 5,000 SCFM and has a Heating Value of Solvent, BTU/# of 15,000.- Waste Water Treatment System

The Waste Water Treatment system is designed to process 115,200GPD of Hydrofluoric Acid and 475,200GPD of Acid Waste Neutralization and accommodate a pH of 5.5-10.5 and a Fluoride PPM of 17.4 and below. The system consists of 4 areas. The waste comes from the plant floor to one of the two waste collection areas Pit #1 & Pit #2, both pits have 1 tank for Alkali and 1 tank for Acids, both also have a spare tank in each area. The Alkali goes from a Pit tank to one of four storage buffer tanks where it is held until it can be processed. The Acids go from a Pit tank to an Acid Buffer tank where it is held until it can also be processed. The Acid is pumped from the buffer tank to a Reaction tank where is it is treated with Lime, Alum Sulfate, Hydrochloric Acid, Sodium Hydroxide Anion Polymer. From there it goes to a sedimentation tank, where it is separated to a solution or sludge; the sludge goes to a thickener tank then onto the filter press; the liquid solution goes to one of the Alkali buffer tanks to be processed through that system. The Alkali waste goes from one of the buffer tanks to a Neutralization tank where it is treated with Caustics or Hydrochloric Acid to adjust the pH and Fluoride PPM then sent to city drain. - Acid, Alkali, and NOX Scrubbers

Removal and Shipping

Retronix Semiconductor

9101 Wall St, Suite 1030

Austin, Texas 78754

817-380-8893

[email protected]

DFW Movers & Erectors, Inc

(817) 222-3200

3201 N Sylvania Ave #115

Fort Worth, TX 7611

Navis Pack & Ship – Austin/San Antonio

Bryan or Arlene

9232 Research Blvd, Austin, TX

Tel: (512) 997-9674

Tel: (866) 688-9338

[email protected]

Partner Details

Silicon Valley Disposition is not affiliated with any machinery rigging, transport, or shipping company. We provide names and contact details of available companies as a courtesy to our buyers. Silicon Valley Disposition neither endorses nor assures the services of any machinery rigging, transport, or shipping company, and is not liable for any issues resulting from their actions. Buyers should choose their service provider, ensuring they submit necessary forms and insurance certificates to Silicon Valley Disposition.